Jiaxing Yaxin Label Printer Co., Ltd. is a well-established entity known for its large scale, strong business capabilities, and robust design and production capacities. Founded in 1993, with nearly 30 years of experience, Yaxin adheres to the principles of customer priority and quality first. The company emphasizes innovation through technology, development through quality, and prioritizes talent. With offices and branches established in Shanghai, New York, Los Angeles, and other locations, Yaxin has effectively met the needs of global customers. It has established an efficient production and operational service network, employing over 300 staff and equipped with over 50 advanced Swiss “Muller” label weaving machines, multiple German Heidelberg printing machines, and various supporting equipment. Committed to the eternal promise of “good quality, reasonable price, and prompt service,” the company is open to various forms of cooperation domestically and internationally, aiming to provide high-quality services to an increasing number of customers.

Introduction Video

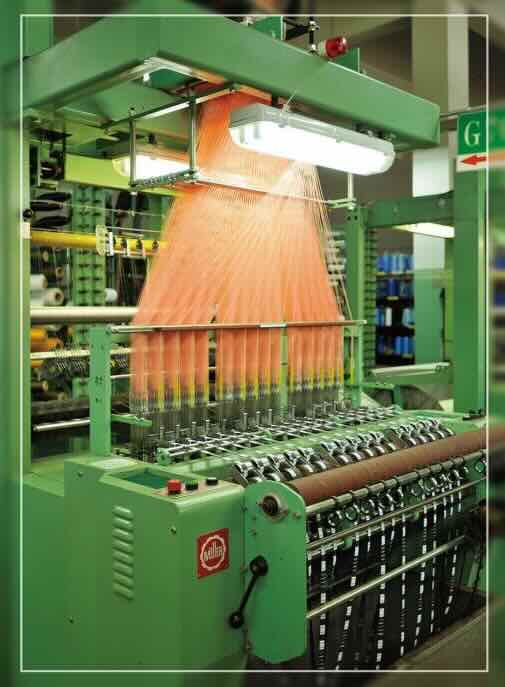

Woven Label Department

Produce world-class products and equipped with world-class facilities. Since 1993, the company has been introducing Swiss “Muller” label weaving machines and computerized label design systems. Currently, we possess an array of machinery including the MBJ2, MBJ3, MBJ3.8 electronic warp knitting machines, GF20 automatic label cutting and folding machines, MVC2.8 crochet label machines, and Muller ultrasonic edge cutting machines, forming the foundation of our label production system. With robust production and supply capabilities, we can produce approximately one million various woven labels per day, encompassing a wide range of widths, color combinations, and the latest international fashion styles, meeting unique and specific requirements. Our hardware and software ensure that customer demands for production speed, volume, and quality are met.

The variety and innovation of woven label products are rich, utilizing edge-burning machines and crochet machines for production. These products are widely used in garments, headwear, toys, footwear, and more. Additionally, the products meet relevant standards in terms of water resistance, colorfastness, adhesive properties, resistance to acid and alkali sweat stains, resistance to dry friction, and material odor, making them practical and environmentally friendly.

Color Printing Department

Having supporting equipment for automated printing, hot stamping, embossing, and laminating, we can produce up to one million various colored hang tags and colored packaging items every day.

Silk Screen Printing Department

We specialize in producing garment printing products and various personalized items. With seven production lines, each spanning 50 meters in length, we have flatbed four-color label printing machines as well as advanced flexographic printing machines and various semi-automatic silk screen printing equipment, including a four-color and seven-color double-sided high-speed rotary press.

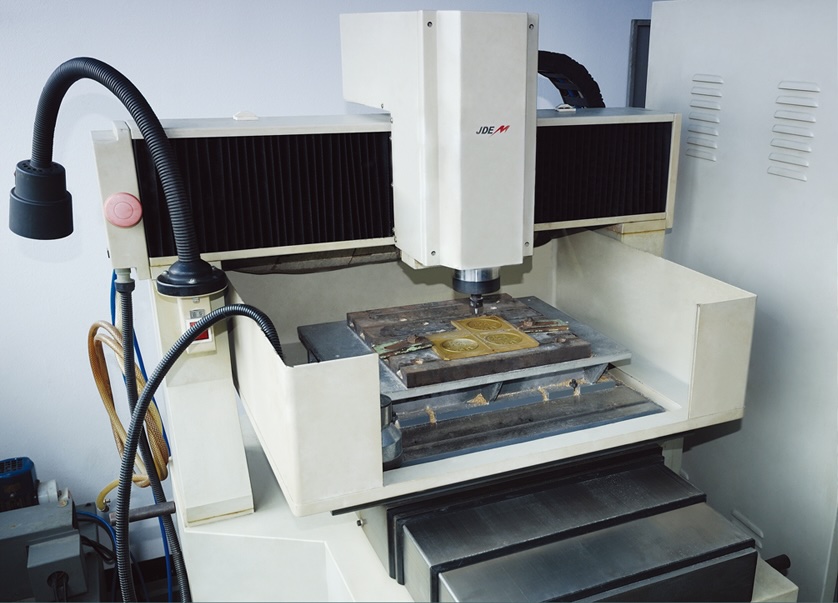

Rubber Department

We specialize in the production of rubber stamp products, equipped with advanced computer engraving systems and a complete production line, including TDEMP computer engraving machines, 2X-30 vacuum systems, professional mold replication systems, and skilled technicians. We can produce exquisite products of various styles and designs.

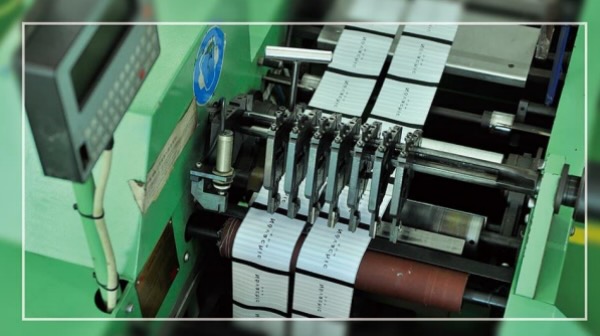

Finishing Department

The Swiss Muller ultrasonic strip cutting machine, ultrasonic cutting machine, label cutting and folding machine, hot stamping and electrochemical aluminum embossing and cutting machine, punching machine, and other equipment can process products according to customer requirements, meeting diverse needs and demands for customer products.